I can’t believe this is the fourth year running this sandwich. We are working hard at fine-tuning the sandwich roll-out process. Back when it was just one truck, the lines of communication were just me talking to Ayr. Now with 9 managers and twice as many team leaders, our seasonal sandwiches haven’t always rolled out smoothly (ex: Harvard Square would never get the new sandwich on Day 1). So far this is the cleanest to date, partially due to some really good coordination between the kitchen and the location managers. Read on if you’re interested in the world of culinary operations; if you’re just hungry, head to your nearest Clover to try.

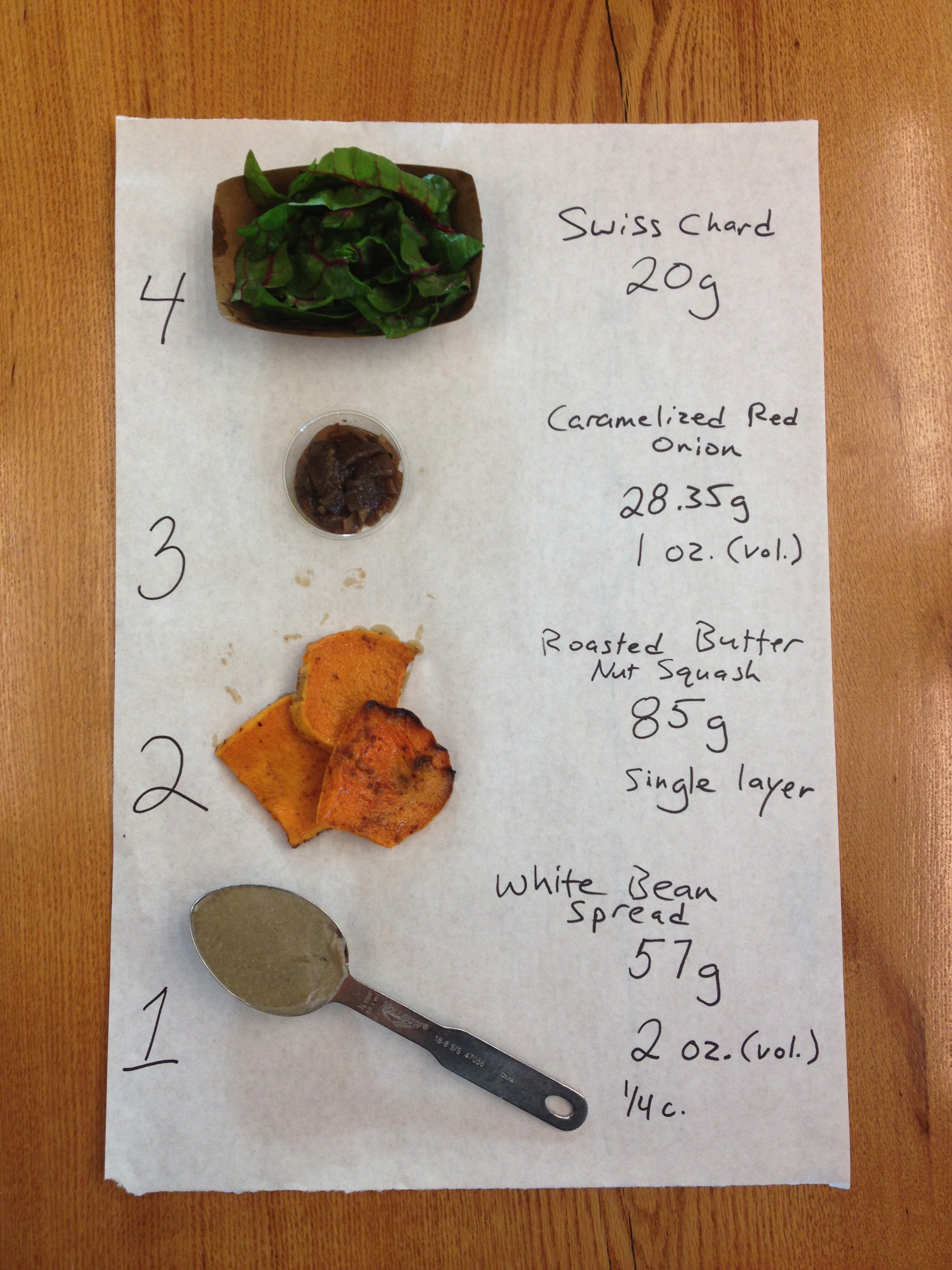

We have to test the recipes and taste with customers. We fine tune batch sizes, record yields, calculate food costs. We tell the packers how many of each to send to a given location. Each manager gets a training guide (pictured above), to assist the sandwich makers with visuals. We’ve also implemented a policy that every sandwich maker eats a full seasonal sandwich before they are allowed to make one for you. It’s a lot of coordination, and we are getting better at it.

You can test how this process is working. Try one, tell us what you think.