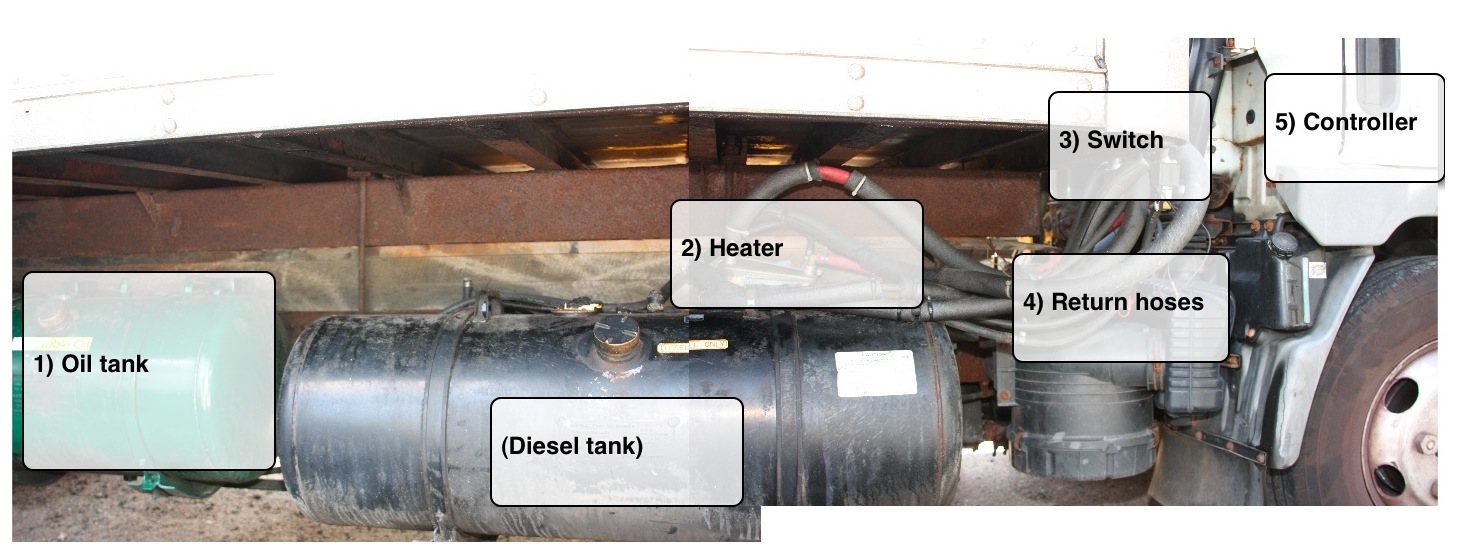

For those interested in the details, here’s a quick summary of how these vegetable oil conversions work. Apparently the diesel engine can run on vegetable oil just fine, so long as it is (A) the right temperature (~150°F), and (B) doesn’t contain water or particles. It seems that (B) has more of an impact on the life of your fuel filters than anything. So here’s the layout:

- An oil tank is added to supplement the existing diesel tank. The oil tank typically has a heater inside or at the feed pump.

- A heater (typically a heat exchanger that uses the existing engine coolant) is connected in-line to heat the oil on the way to the engine

- Electrically-controlled switches are added between the tanks and the engine

- A bunch of hoses must be added. Hoses for the oil send and return (for some reason diesel engines send excess oil to the engine, the remainder is returned to the tank), hoses for the heat exchanger, extra hoses for the existing diesel fuel in order to run it through the switches

- A controller manages the switches and in some systems the heaters/ heat exchangers

People with these conversions typically fill both tanks (oil and diesel), start on diesel, use the controller (in the cab) to switch to oil after the engine has warmed up. It’s important that the oil be filtered of both water and particles.