(If not for the Impossible shirt I could claim this was me. My son Blue and I made a rhubarb pie last weekend. First time he has made pie. I looked EXACTLY like this when I was his age.)

My love of rhubarb is no secret.

If you’ve been eating at Clover for a while you might have noticed we were late to get rhubarb on the menu this year. About 2 weeks later than availability.

There is the simple answer: we’ve been busy doing a lot of things. We just launched the Impossible Sausage Egg and Cheese sandwich that has been selling bonkers at our restaurants (despite being super expensive). We rolled out a new coffee program company wide with a new focus on New England-only coffee roasters, tweaks to our pour over set-up, new “express” coffee offerings, Cafe Au Lait, and a chicory cold brew on nitro that is so yummy. We’d added soups as an add-on option to sandwiches. And we’ve started rolling out retail/ grab-and-go offerings. And we’re on the eve of moving our drinks to portable packaging so that you can throw them in your bag. All of this while the Clover App has been growing at crazy rates.

So we’ve been busy. This is the simple answer to why the rhubarb launch is a couple weeks later than availability.

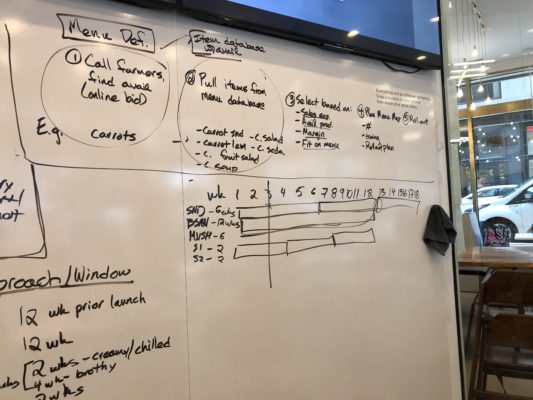

The more complicated answer has to do with how we match our menu to seasonal changes. In theory Clover’s menu works like this:

- We ask farmers what they have available

- We look up recipes that use that ingredient

- We make and well those items until that ingredient is out

- Repeat, repeat, repeat

This is why our menu changes day to day, based on growing seasons, not artificially 4 times per year based on calendar seasons. The tech and systems (including our own Point of Sale system and in-house developed app) were developed to enable this are where most of our effort has gone over the past 10 years. Nobody does this. I don’t think anybody would think it possible if Clover wasn’t doing it. I think in 15 years this is what everybody will be doing, at least I hope.

As I dug into the rhubarb I found that we were overdue for an update to our sourcing approach. We’ve worked over the past 3 years to refine our product development approach. Which is amazing now. But we hadn’t taken the same sort of structured effort to define and improve our sourcing approach. And the truth is that it’s more complicated than I outlined above. Some items (e.g., a new sandwich) represent a more major launch and we need time to plan. Other items (e.g., drinks) need to be coordinated so that they not only represent what is available but make sure the offering is varied and attractive visually.

I sat down with Chris (VP of Food) and Martina (Food Development) and Greg (COO) for a couple of hours last week and we sketched out a better defined approach. We’re breaking down the entire menu by slot/ category of item. Down to a fine level of detail. And then we’re setting requirements/ restrictions for each category (e.g., sandwiches need to be locked down 6 weeks prior to launch, including all sourcing). If this works well it will be the design structure for a machine assisted version of menu planning. And at some point I’d love to have an electronic marketplace where farmers can go to offer up what they have.

If it all works you’re going to see the most vibrant Clover menu ever over the coming months. And even though we do a great job now at buying locally we can do better. If we bring local sourcing in May from 40% up to 60% or in September from 80% to 90% that’s a lot of $ for local agriculture.